In the rapidly evolving landscape of modern industries, the role of a reliability engineer has become more crucial than ever. With the integration of advanced technologies such as Artificial Intelligence (AI) and open platforms, businesses are increasingly focusing on maintaining high levels of reliability and safety. This article delves into the multifaceted responsibilities of a reliability engineer, exploring how their expertise is pivotal in ensuring the seamless operation of systems and processes.

Understanding the Role of a Reliability Engineer

A reliability engineer is tasked with the responsibility of ensuring that systems and processes within an organization operate efficiently and without interruption. They focus on identifying potential failures, analyzing risks, and devising strategies to mitigate them. This role is particularly significant in industries where even minor disruptions can lead to substantial financial losses or safety hazards.

Core Responsibilities

-

Failure Analysis: Reliability engineers conduct thorough investigations into system failures to understand root causes. This involves using tools like Failure Mode and Effects Analysis (FMEA) and Root Cause Analysis (RCA) to predict and prevent future issues.

-

Predictive Maintenance: By employing advanced data analytics and AI, reliability engineers can anticipate equipment failures before they occur, allowing for timely maintenance and reducing downtime.

-

System Optimization: Through continuous monitoring and analysis, reliability engineers identify areas for improvement within systems and processes, optimizing performance and efficiency.

-

Risk Management: Developing and implementing risk management strategies to address potential safety and reliability issues is a key aspect of their role.

Integrating AI for Enhanced Reliability

The integration of AI in industries has revolutionized the way reliability engineers approach their tasks. AI enables the analysis of vast amounts of data quickly and accurately, providing insights that were previously unattainable.

AI in Predictive Maintenance

AI-powered predictive maintenance involves using machine learning algorithms to analyze historical and real-time data, predicting when equipment is likely to fail. This proactive approach allows organizations to perform maintenance activities only when necessary, reducing costs and minimizing downtime.

import numpy as np

from sklearn.ensemble import RandomForestRegressor

# Example of a simple predictive maintenance model

# Feature set includes sensor readings and operational data

features = np.array([[0.5, 0.7], [0.3, 0.8], [0.6, 0.6]])

# Labels represent time to failure

labels = np.array([10, 5, 7])

# Train a Random Forest model

model = RandomForestRegressor()

model.fit(features, labels)

# Predict time to failure for new data

new_data = np.array([[0.4, 0.75]])

predicted_failure_time = model.predict(new_data)

print(f"Predicted time to failure: {predicted_failure_time[0]} days")

This code snippet demonstrates a basic predictive maintenance model using a Random Forest regressor. By analyzing sensor readings and operational data, the model predicts the time to failure, allowing for timely interventions.

The Importance of Open Platforms

The adoption of open platforms such as Tyk and their capabilities like “Additional Header Parameters” is transforming how reliability engineers perform their roles. Open platforms provide the flexibility and scalability needed to integrate various tools and technologies seamlessly.

Open Platform Benefits

-

Scalability: Open platforms allow organizations to scale their operations efficiently, accommodating growth without compromising on reliability.

-

Interoperability: These platforms support the integration of diverse technologies, facilitating a cohesive ecosystem that enhances reliability engineering efforts.

-

Customization: With open platforms, reliability engineers can tailor solutions to meet specific organizational needs, ensuring optimal performance and reliability.

Addressing Enterprise Safety with AI

As industries become increasingly reliant on AI, ensuring the safe use of these technologies is paramount. Reliability engineers play a crucial role in this aspect by implementing strategies that safeguard both the enterprise and its stakeholders.

Ensuring Safe AI Deployment

-

Bias Detection and Mitigation: Reliability engineers work to identify and address biases in AI algorithms, ensuring that decisions made by AI systems are fair and unbiased.

-

Transparency and Accountability: Establishing clear protocols for AI decision-making processes helps maintain transparency and accountability within the organization.

-

Continuous Monitoring: Ongoing monitoring of AI systems ensures that they function as intended and that any anomalies are promptly addressed.

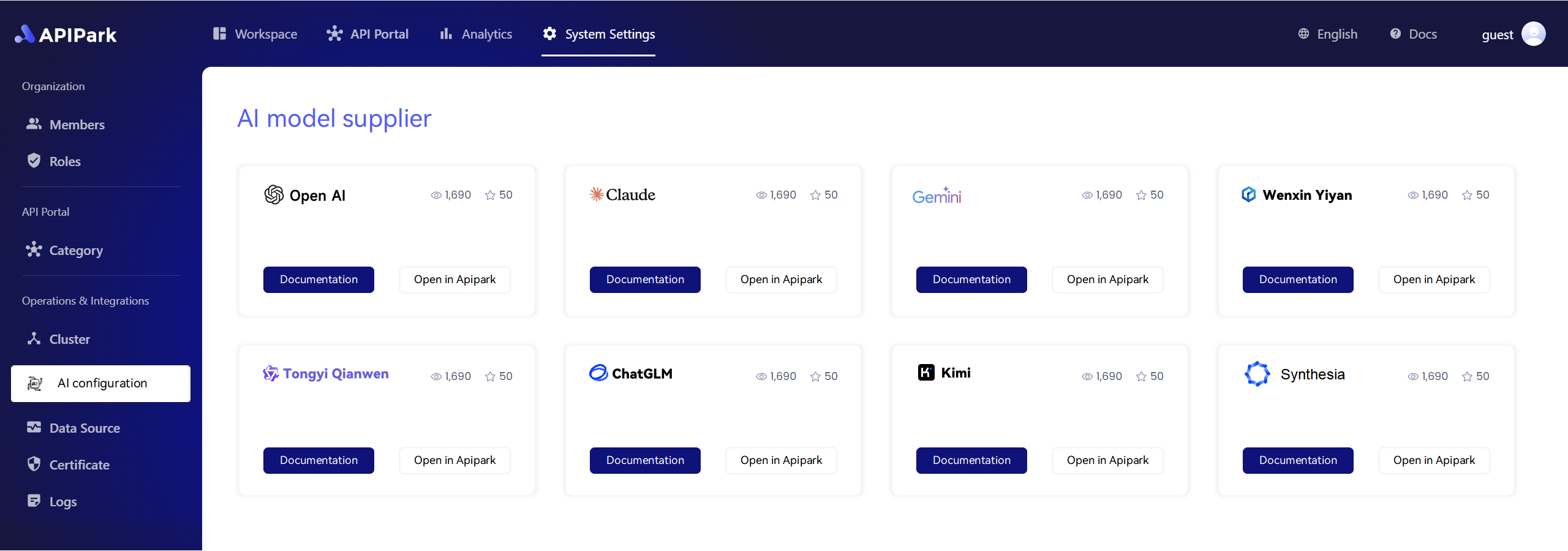

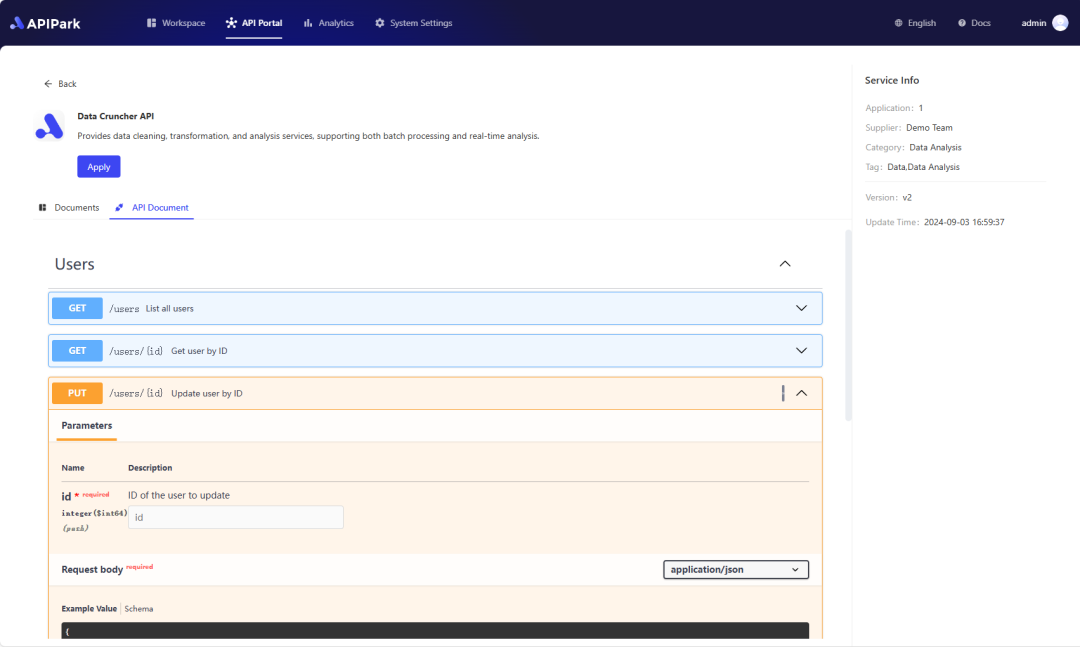

APIPark is a high-performance AI gateway that allows you to securely access the most comprehensive LLM APIs globally on the APIPark platform, including OpenAI, Anthropic, Mistral, Llama2, Google Gemini, and more.Try APIPark now! 👇👇👇

Challenges Faced by Reliability Engineers

While reliability engineers play a vital role in modern industries, they also face numerous challenges. These challenges can stem from the complexity of systems, evolving technologies, and the need to balance performance with safety.

Overcoming System Complexity

Systems in modern industries are often complex, comprising numerous interconnected components. Reliability engineers must navigate this complexity to identify potential points of failure and ensure overall system integrity.

Keeping Up with Technological Advancements

As technology continues to advance at a rapid pace, reliability engineers must stay abreast of the latest developments to effectively apply them in their work. This requires continuous learning and adaptation.

Future Trends in Reliability Engineering

The future of reliability engineering looks promising, with several emerging trends poised to redefine the field.

Increased Use of Digital Twins

Digital twins, virtual replicas of physical systems, are becoming increasingly popular in reliability engineering. They allow for real-time monitoring and simulation, enabling engineers to predict and mitigate potential issues before they occur.

Enhanced Data Analytics

Advancements in data analytics are empowering reliability engineers to make more informed decisions. By leveraging big data, they can gain deeper insights into system performance and identify trends that may impact reliability.

Conclusion

The role of a reliability engineer in modern industries is both challenging and rewarding. As organizations continue to integrate advanced technologies like AI and open platforms, the expertise of reliability engineers becomes indispensable. By focusing on predictive maintenance, risk management, and safe AI deployment, these professionals ensure the seamless operation of systems, safeguarding businesses and their stakeholders. As we look to the future, the continuous evolution of reliability engineering promises to drive further innovations and improvements across industries.

🚀You can securely and efficiently call the Claude(anthropic) API on APIPark in just two steps:

Step 1: Deploy the APIPark AI gateway in 5 minutes.

APIPark is developed based on Golang, offering strong product performance and low development and maintenance costs. You can deploy APIPark with a single command line.

curl -sSO https://download.apipark.com/install/quick-start.sh; bash quick-start.sh

In my experience, you can see the successful deployment interface within 5 to 10 minutes. Then, you can log in to APIPark using your account.

Step 2: Call the Claude(anthropic) API.